About me

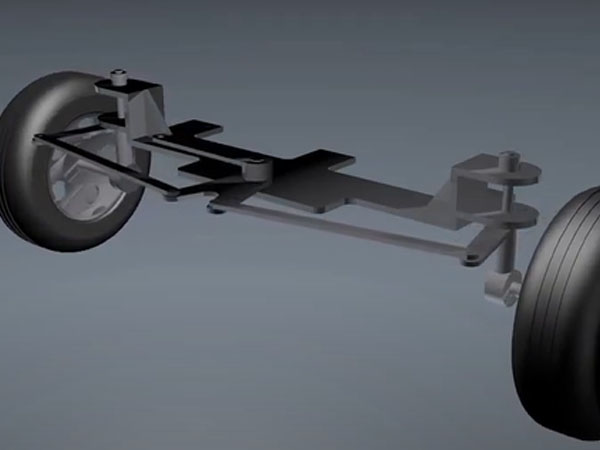

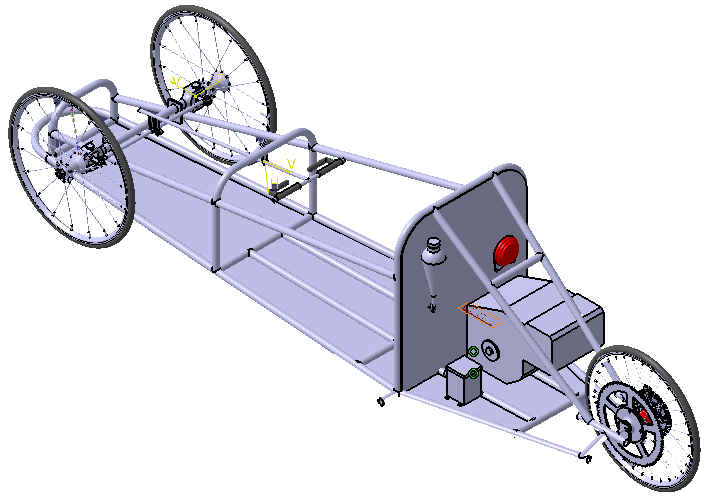

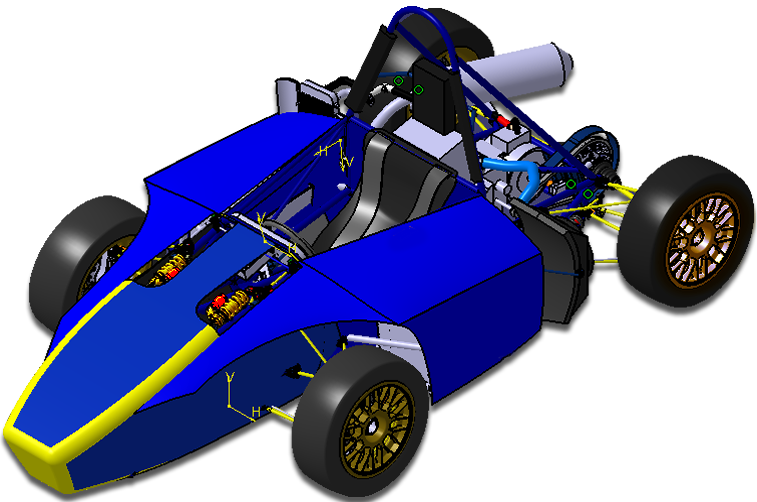

Growing up I was super fascinated about how things worked and how they were made. It was this desire of mine that would often get me into trouble. Rather than finding a kid playing with toys, you would come back to having the toys completely disassembled. I just had to know how things worked, were put together and what the right tools were to find out. It was this desire of mine that led me to doing my Bachelors in Mechanical Engineering. I then followed this by completing my Masters in Mechanical Engineering with a focus on Advanced Materials and Manufacturing.

It has often been said that it is easier to design a product than to manufacture it. This is where I want to help discover ways to speed up the process. Check out what I'm up to below and explore my portfolio!

What i'm doing

-

Research

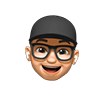

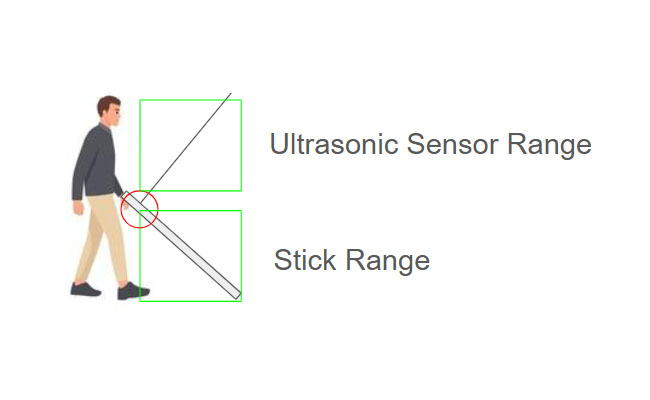

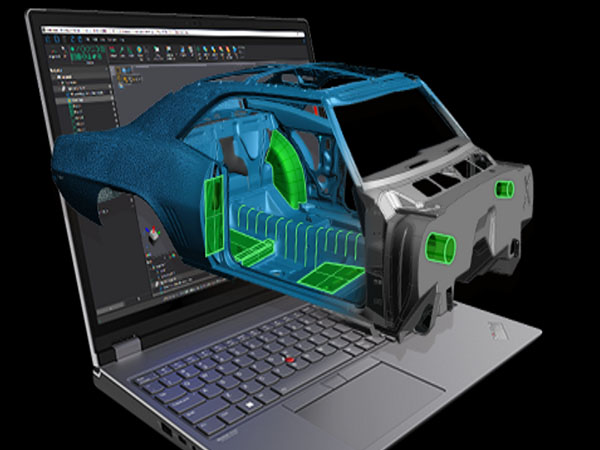

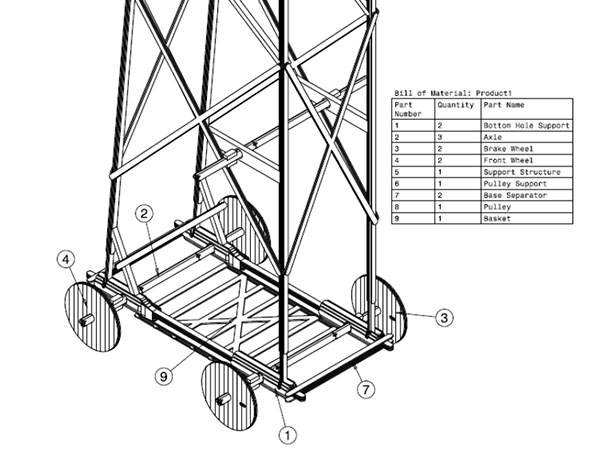

Understanding ways to make manufacturing quicker and efficient

-

Web development

High-quality development of sites at the professional level.

-

Mobile apps

Professional development of applications for iOS and Android.

-

Content Creation

Making content to make engineering a not-so-hard literature

-

PhD Prep

Gaining essential skills to integrate advanced manufacturing, computer vision and batteries in engineering!